While many manufacturers in the optical sector are located on functional industrial estates, Focus Optical Laboratories enjoys green and leafy surroundings at Priory Farm, outside of Redhill in Surrey.

‘We set up here in 2000 so it will be 16 years in October,’ says Matthew Byrne, managing director and owner of Focus Optical Laboratories. ‘At the time we were the first business to take up residence here but now there are about 10 others doing various things. I originally set up with a partner but he stopped playing an active role when he moved to Australia in 2006. About two years ago I began the process of buying him out and today I solely own the company.’

Last visited by Optician back in 2011, Focus has remained an independent lab in the intervening years.

‘Business has been largely steady with a few ups and down in the past five years,’ says Byrne. ‘We do want to grow but it is also important not to endanger the quality of service we provide to our existing clients.’

Improvements in efficiency mean that Byrne’s work force of six (consisting of one driver, two full time technicians, one computer and technology specialist, a customer service administrator and an auxiliary worker who covers where needed) are able to exceed previous output at the lab.

‘It is hard competing with the big companies,’ says Byrne. ‘We obviously don’t have entire divisions working on our marketing materials and while we offer freeform products we don’t manufacture them here. However, we are free to make adjustments to the business quicker and offer a more personal service.

‘We do offer an express option for lenses now. This guarantees that any surfaced single vision, bifocal or varifocal lens in any index, with any coating in photochromic, clear or polarised will be delivered door-to-door within four days for a surcharge of £10 per pair of lenses. In order for us to provide this service it is good not beholden to one any one supplier.’

Focus Optical has worked just outside of Redhill since 2000

So are optical practices becoming more demanding in their expectations of suppliers?

‘It’s been going that way ever since we started,’ says Byrne. ‘But the need to keep improving is what keeps us on our toes and makes us perform. It is because of this need to improve that we’ve worked hard over the past couple of years to develop a custom-made database and use technology throughout the lab to track jobs.

‘I wanted the system to be accessible from anywhere so it needed to be hosted remotely and I wanted freedom in adapting it to our needs. From the outside it does not look that different but it does mean that we can now automate a lot of our monitoring and updating. The database has worked very well – the only issue was that the remote hosting meant when the broadband went down one day we had to run the lab via a internet tether from my mobile.’

Byrne has also been working on integrating near-field communication (NFC) technology into the lab which will take over from the current barcode scanning system in tracking jobs through the various stages of production.

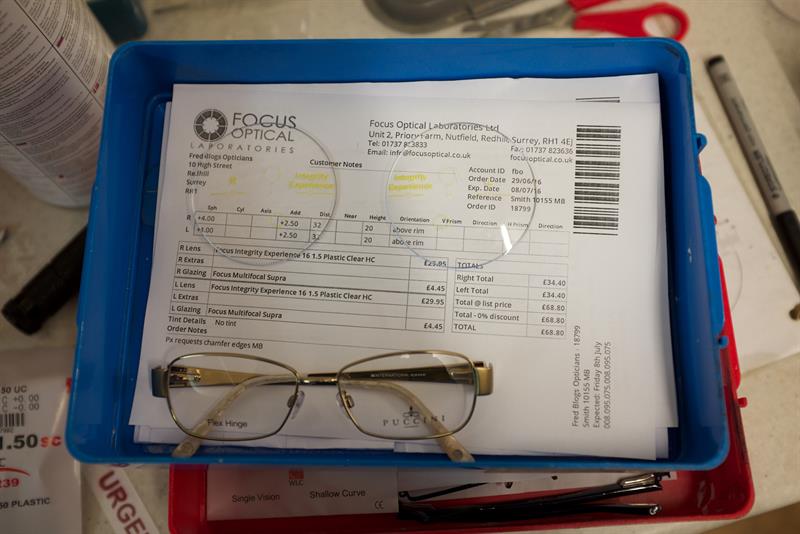

A typical tray at the office

‘We will soon be using NFC tags on all jobs,’ says Byrne. ‘This is how larger labs work and will definitely add to our efficiency. It will tell us not only when a job is expected but also what stage it is at.

‘Last year we were so busy at times that our service was really stretched and we had to find ways to improve – through first the database and now the NFC. When a job gets input to the system we can already give an ETA for the various lenses on our database. The next step will be to look at the figures of how long different products are taking so we can fine-tune our ETAs and make it more accurate for our clients. It is an ongoing process.’

The company offers an express service which guarantees delivery in four days

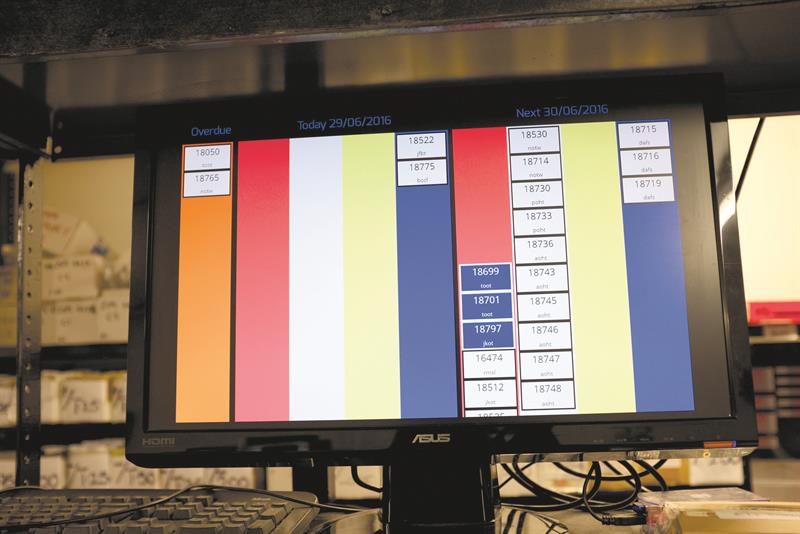

One physical manifestation of these developments is the lab’s ‘flight departure board’ – so called because it resembles the constantly updated information screen found in airports.

‘This displays where the jobs are in the lab and when they are due – it separates each of the days out and highlights what the priorities are,’ says Byrne. ‘It is a sure way to stop jobs being forgotten or mislaid. We used to work with ETAs and labels on the job trays but if you have 100 jobs in the lab it is too easy to miss one. I wanted a system where we have a last point of check. I can tell customers exactly what is happening and be sure nothing has been missed. The crucial thing about providing a good service is that it is a consistently good service.’

Asked to describe a typical day at Focus, Byrne says he gets to the facility shortly before six to open up.

‘I have a strong coffee and get down to identifying the priorities for the day ahead. First thing is getting the jobs ready for delivery on the first route, which covers Kent, at 9am. The van will return with new jobs from those clients and in the interim we’ve got the second route, which goes to practices in Surrey, ready. The second route goes out at 11am and new jobs come back from there too. Around 80% of our orders come via the delivery routes so they arrive once each route has been completed and get ordered and input throughout that day.’

The flight departure board at the heart of production prevents any jobs from going astray

The lab is considering extending its delivery area into West Sussex and south Surrey. Orders also come and go via delivery services.

‘It can be frustrating if the delivery services are delayed but we are prepared to do special van runs or send by taxi in order to meet any guarantees we have given our clients. When someone really needs something we come through for them – it is one of the reasons practices use us.’

Through the rest of the working day the lab works through its jobs in order of priority, generally closing around between 5.30pm and 6pm.

Asked why practices use Focus and what the future holds for the lab, Byrne replies: ‘We are generally on first name terms with our customers and they trust us to look out for them. We have access to all available lenses so we are sometimes able to save our client’s money – our view on the best lens for the job is completely unbiased as we are totally independent.

‘I’m really proud of what we have developed with our database and the monitoring system. In the future I really want to offer a comprehensive lens reference guide, where a customer can say they need a certain type of varifocal, for example, of a certain quality and in a certain prescription and be displayed what is available.’