Light is a non-ionising electromagnetic radiation produced by various natural and artificial sources. The optical range of radiation extends from about 100nm in the ultra-violet (UV) region of the spectrum up to 106nm in the infrared (IR). However, the visible waveband, the part of the electromagnetic spectrum that stimulates the eye and gives rise to vision, lies between 380nm and 780nm.

The eye is most sensitive to wavelengths in the region of 555nm which lie in the yellow-green portion of the spectrum. Tinted lenses (or filters) are usually employed to protect the eye against excessive solar radiation, reduce eyestrain and increase visual perception. In addition, specialist filters are used in some industrial environments. A tinted lens is described as a lens (generally an absorptive lens) that has a noticeable colour in transmission.

As with most topics within optometry and ophthalmic dispensing, multiple descriptions are used to define specific terms. It is therefore useful to review the terminology used in BS EN ISO 13666:2012 Ophthalmic optics – Spectacle lenses – Vocabulary. This International Standard defines the basic terms relating to ophthalmic optics, specifically to semi-finished spectacle lens blanks, finished spectacle lenses and the fitting of spectacle lenses. The terms relating to tinted lenses found in the above document are as follows:

Absorptive lens: A lens designed to absorb a certain range or proportion of incident radiation.

Tinted lens: A lens (generally an absorptive lens) having a noticeable colour (including grey) in transmission.

Colourless lens: A lens with no noticeable colour in transmission.

Clear lens: A lens with a luminous transmittance falling within the range of Category 0 of ISO 8980-3:2003. (Such a lens may have a pale tint).

Uniformly tinted lens: A lens made from material in which either the tint is incorporated throughout, or which, after manufacture, is surface-treated to provide a uniform tint. Where the tint is dispersed uniformly through the material of the spectacle lens, ie a solid tinted lens, the luminous transmittance will vary with the lens thickness as a result of its dioptric power. Such a variation does not mean that the lens is classed as a gradient-tinted lens.

Gradient-tinted lens or graduated-tinted lens: A lens having a controlled variation in tint (or transmittance) over the whole or part of the lens.

Double gradient-tinted lens: A gradient-tinted lens in which tints of one or more colours are used, one colour fading in one direction, the other in the opposite direction, both along the same gradient-tinted direction.

Gradient-tinted direction: In a gradient-tinted or double gradient-tinted lens, the direction along which the variation in tint occurs. This is assumed to be vertical unless otherwise ordered.

Photochromic lens: A lens which reversibly changes its luminous transmittance characteristics depending upon the intensity and wavelength of the radiation falling upon it. The lens is designed to react to wavelengths within the solar spectral range, chiefly 300nm to 450nm. The transmission properties are usually affected by ambient temperature.

Spectral and luminance transmission factors

So how is the density of a tint described? In practice it is important to remember that the density of a tint may be described by stating its transmission or its absorption. A lens with an 80 per cent transmission is very different to a lens with 80 per cent absorption!

Spectral transmission factor (STF) is the fraction of the original incident light transmitted by the lens for a particular wavelength. It can be expressed as a decimal or as a percentage. If the STF is plotted against a series of wavelengths then a transmission curve is produced.

Ideally, transmission curves should be plotted for a 2mm thick sample of material covering wavelengths from 300 to 800 or 1000nm. However, if special IR or heat absorbing properties are claimed then the transmission curve should extend to 2,000nm or above. Transmission curves are obtained by using a spectrophotometer.

Luminous transmission factor (LTF) expresses the overall effect of a filter on a standard eye viewing a standard light source. The standard source currently used is determined by the Commission Internationale de l’Eclairage (CIE) as standard illuminant D65, which replicates a daylight source.

The use of LTF allows practitioners and manufacturers to obtain a single figure for each tint, so that they can be compared more easily. The LTF takes into account the fact that the eye is not uniformly sensitive to all radiations. In photopic conditions the eye is maximally sensitive to approximately 555nm and least sensitive to the red and blue ends of the spectrum.

The manufacture of tinted spectacle lenses

There are a number of ways in which a tint can be produced depending on the lens material and level of production required. In glass materials, solid, coated, bonded and photochromic tints are available. Glass solid tints including photochromic lenses absorb unwanted light while coated tints generally reflect unwanted light. However, absorptive coatings are available on glass lenses.

Solid glass tints (or filters) have their colour uniformly distributed throughout the material during manufacture, resulting in an uneven appearance with high powers (the right hand lens in Figure 1, and Figure 2). Solid tints in glass can be produced by adding metallic oxides.

[CaptionComponent="2654"]

The addition of cobalt oxide results in a blue lens, chromium oxide a green lens, magnesium oxide a violet lens, and uranium oxide a yellow lens; cerium oxide results in UV absorption properties, iron absorbs IR radiation and silver halide crystals result in photochromic properties.

[CaptionComponent="2655"]

The colour of a solid tint affects the transmission curve produced and also gives an indication of its transmission properties. Pink or brown solid glass filters absorb UV while green solid glass filters absorb UV and IR. Grey solid glass filters absorb UV and give less colour distortion; amethyst absorbs yellow and improves contrast and yellow solid glass filters absorb blue light and improve contrast and definition in hazy conditions.

Glass lenses can also be vacuum coated, resulting in a lens with an even (equi-tint) appearance (the left hand lens in Figure 1). In Figure 3 note that the lens viewed ‘edge-on’ appears white as the tint has been applied to the surface of the lens only. This appearance would not be apparent if a solid tint was viewed in the same way. Coated tints (filters) generally reflect unwanted wavelengths of light.

[CaptionComponent="2656"]

Various colours are available, although unlike solid glass filters the colour does not indicate the transmission properties of the lens. Bonded glass tints are also available where a very thin tinted component is bonded to a carrier white lens. The tinted component can be a fixed solid tint or photochromic. The photochromic option (Figure 4) was popular for use with high myopic prescriptions before the introduction of plastics photochromic lenses. A bonded fixed tint lens blank is shown in Figure 5.

[CaptionComponent="2657"]

The vast majority of tints applied to plastics lenses are dip-dyed. The finished lens is placed in a hot photographic dye and the dye penetrates the surface up to a depth of about 1mm, producing an even appearance. The tinted lens absorbs unwanted light, and like coated glass lenses, the colour is not an indication of transmission properties. Most colours and gradient filters are available.

For the mass production of tinted plastics lenses such as sunglasses, clear lenses with a built in UV blocker are manufactured and then tinted en masse, using carefully controlled slow penetrating dyes. For normal prescription work, faster penetrating dyes such as those found in many in-house labs are used. However, the results are sometimes unpredictable, difficult to replicate and lack spectral accuracy.

This method is also used to tint coatings where the substrate material itself cannot be tinted. Some manufacturers have developed laminating and bonding processes that allow wafer-thin tinted films to be bonded to or sandwiched within the lens, providing consistent colour accuracy and the opportunity to combine features like contrast enhancement, polarisation and photochromic elements within a single lens.

[CaptionComponent="2658"]

It is interesting to note that solid plastics tints are available. With these lenses the casting material is dyed and like a solid glass lens, it can have an uneven appearance. Plastics solid tints absorb unwanted light and are usually used for specialist tints.

Infrared radiation and IR absorbing filters

Infra-red radiation (IR) has wavelengths between 760 and approximately 500,00nm. Ocular tissues absorb radiations around 800 to 1,400nm and IR radiation produces a sensation of warmth so there is awareness of the hazard. Exposure to IR causes heat cataract, possible retinal and choroidal lesions and irreversible bleaching of retinal visual pigments (sun blindness). Exposure occurs due to staring at the sun, working in a furnace and with explosions.

Protection from IR is best provided by a glass solid tint which employs ferrous oxide placed in the glass melt to selectively absorb IR, resulting in the classic green colour. The most commonly quoted example of an IR absorbing filter is the Ray-Ban G15 lens (Figure 6) which has a peak transmission at around 550nm. CR39 and other plastics materials do not produce good IR absorbing filters as heat degrades plastics material. An exception to this is polycarbonate which can be used to absorb IR.

[CaptionComponent="2659"]

Sun protection, ultra-violet and UV absorbing filters

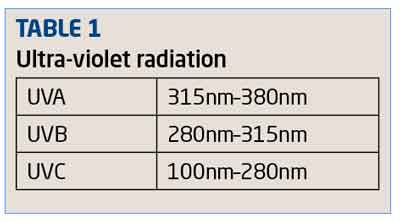

The risks of exposure to excessive levels of visible light and ultra-violet (UV) are well known and it is important that practitioners appreciate these risks when advising a patient on an appliance for sun protection. UV radiation ranges from around 100 to 380nm and is divided into the three groups listed in Table 1.

The human eye provides protection from excessive bright light by reducing the pupil aperture and from most UV by filtering out UVB in the cornea and UVA in the crystalline lens. UVC is normally not considered an issue as it is absorbed by ozone in the atmosphere.

UVB from 280 to 315nm is absorbed by the cornea but can cause inflammation of the cornea and epithelial cell loss (snow blindness). UVB from 295 to 315nm can reach the retina and produces similar effects to UVA. UVA (315 to 380nm) penetrates more deeply into the eye and can cause damage to the crystalline lens and retina.

UV radiation does not stimulate the sensory nerves so there is no warning of exposure and symptoms can be delayed for up to 12 hours and short intermittent exposure can produce the same effects as one long exposure. Ocular effects of exposure to UV include itching, watering, photophobia, swelling of the eyelids, impaired dark adaption and nuclear sclerotic cataract.

In addition, UV can increase the rate of development of age-related cataract and is implicated in the pathogenesis of macular degeneration. Exposure to UV may also occur in occupations such as welding, clinics using UV lamps and out-of-doors activities. Any UV filter should absorb all radiations below 360nm.

Glass UV absorbing tints usually contain cerium oxide in the melt, resulting in a pink or brown tint. UV protection can be supplied without residual colour, but if protection is required within the blue end of the visible spectrum then there will be some colour.

As pupil dilation occurs when dark tinted lenses are worn it is important that a tinted lens incorporates an appropriate level of UV absorption in order to protect the ocular structures from exposure to UV. Some materials for example, like polycarbonate, Trivex and photochromic lenses provide UV protection, but for all other lens materials, specification of an additional UV absorbing filter is essential when tinted lenses are to be ordered.

Although some debate exists as to the exact boundary between visible light and UV, it has become widely accepted to specify a UV-absorbing filter of 400nm, commonly referred to as a UV400 filter. Activities that specifically benefit from UV protection include climbing and flying where UV increases by about 5 per cent for every 1,000 feet of altitude.

Even when a tint is not required, the inclusion of a UV400 filter is advocated by many practitioners, especially when dispensing spectacles to children and, although rarely seen today, aphakic patients since the eye’s natural ability to absorb UVA has been lost with the removal of the crystalline lens. Specifying a tinted lens with a UV400 filter has also been shown to benefit patients with the following conditions:

? Early cataract

? Macular degeneration

? Diabetic retinopathy

? Glaucoma

? Aniridia

? Albinism

? Optic atrophy

? Corneal dystrophy

? Retinitis pigmentosa.

Tinted lenses

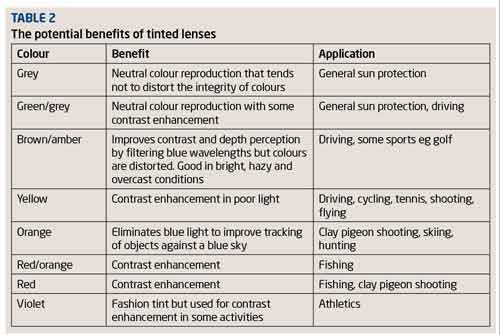

Spectacle tints are often considered to be a fashionable addition, but the functional applications of tints are far more important especially when they are used to enhance contrast for driving or sporting activities. Some examples are listed in Table 2.

Figure 7 compares the transmittance of a CR39 lens that incorporates a UV-absorbing filter with an untreated lens.

[CaptionComponent="2660"]

[CaptionComponent="2661"]

Transmittance of tinted lenses

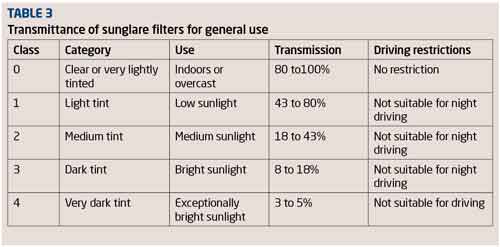

Perhaps the most common use of tinted lenses is for driving. Contrast enhancement can certainly improve vision while driving, improving depth perception and the tracking of objects in the visual field. However, care must be taken as there are legal restrictions which must be adhered to. The document EN 1836:2005+A1:2007 (E) (Table 3) gives the transmittance of sun glare filters for general use.

Tinted lenses are graded according to the density of the tint, and all sunglasses should, by law, be labelled and show the filter category number. Lenses with light transmission less than 75 per cent are unsuitable for night driving. Yellow tinted lenses are not recommended for night driving. The tint is likely to be unperceivable anyway if the lens has a light transmission factor of 75 per cent or more to meet night driving requirements.

Lenses with light transmission less than 8 per cent are unsuitable for day or night driving. Due to the light levels within the car, filter category 2 lenses which transmit between 18 per cent and 43 per cent of light are recommended for daytime driving. Filter category 4 lenses only transmit between 3 per cent and 8 per cent of light and are not suitable for driving at any time. Sunglasses with these lenses should, by law, be labelled not suitable for driving and road use.

Recognising the need for specialist driving lenses, some lens manufacturers have developed specific contrast enhancing filters. As these filters are available across a range of lens options they offer the practitioner an opportunity to recommend a specialist driving lens to a wider group of patients. Some commercial sunglass manufacturers have also developed specialist driving ranges like Serengeti (Figure 8) and Maui-Jim (Figure 9), both offering prescription and non-prescription options.

[CaptionComponent="2662"]

[CaptionComponent="2663"]

Photochromic lenses

Photochromic lenses (sometimes referred to as adaptive lenses) are of course lenses that darken and lighten according to levels of ambient UV. Glass photochromic lenses contain silver halide crystals which decompose on exposure to UV and therefore produce a tint. Such a lens is classed as a solid tint, although bonded (equi-tint) glass photochromic lenses are available (Figure 4).

Photochromic lenses use specific molecules that appear transparent in visible light and the absence of UV. When exposed to UV in sunlight, the molecules undergo a chemical change in shape and absorb parts of the visible spectrum, appearing to darken. Traditionally, photochromic lenses were manufactured by introducing substances such as silver chloride or silver halide during the moulding stage to produce a solid glass or plastic photochromic substrate.

Although still available in solid glass and plastics forms, most photochromic lenses are manufactured using plastic materials and photochromic dyes that penetrate 100 to 150 microns below the lens surface to produce a consistent, even colour. Because of the variety in processes used in photochromic manufacture it is important to study the available data on each product, as they do exhibit subtly different performance characteristics.

Plastics photochromic filters employ organic chemicals which have photochromic properties which include spirooxazines or spiropyrans. Transitions lenses are based on spiropyran compound QISO. Plastics photochromic lenses are available in a range of refractive indices including 1.5, 1.54, 1.55, 1.56, 1.59, 1.67 and 1.74. Chemical activation of any photochromic lens depends on UV light and the lens decays back to its un-activated state when the UV light is removed.

Activation (or darkening) is temperature ambient and activation occurs more rapidly at lower temperatures. Luminous transmittance is determined at 25°C ±2°C. Plastics photochromic lenses claim to absorb 100 per cent of UV below 380nm. In the manufacture of Transitions lenses the photochromic layer is imbibed to 0.1-0.15mm which means that the lenses are effectively equi-tinted.

Some plastics photochromic lenses are effectively solid tints where the photochromic material is added to the lens monomer (Sunsensors). Plastics photochromic lenses may also be produced by spin-coating a 30 micron layer of material on to one surface of the lens (Hoya Suntech). This type of application is required where complex lens surfaces such as those required in the manufacture of Hoya’s Hoyalux iD Mystyle V+ need to incorporate a photochromic filter. The Suntech spin-coating process was developed to create a uniformly even photochromic layer onto the freeform surfaces.

Although very popular with some patients, photochromic lenses are often considered as a compromise solution for sun protection by some practitioners. As they rely on a reaction stimulated by UV radiation, historically their use has been restricted primarily to the outdoors as many drivers will testify to their lack of performance inside a vehicle. This situation was addressed by Transitions, with the introduction of Transitions Extra-Active.

Polarisation

Tinted lenses that incorporate a polarising filter offer further benefits to the wearer in addition to any tint and UV absorption. Natural light vibrates randomly in all directions. However, when light is reflected off a horizontal surface such as water or snow it undergoes a phase reversal and is said to be plane polarised. Plane polarised light is light which vibrates in one direction only.

Most of the glare that prompts a patient to ask for sunglasses comes from horizontal surfaces like wet roads, water and snow. Polarised filters are therefore set to an angle that blocks horizontally polarised light from passing through the lens, thus greatly reducing glare (Figure 10).

[CaptionComponent="2664"]

Polaroid is the name of a type of synthetic plastic sheet which is used to polarise light. The original material, patented in 1929 and further developed in 1932 by Edwin H Land, consisted of many microscopic crystals of iodoquinine sulphate (herapathite) embedded in a transparent nitrocellulose polymer film. The needle-like crystals are aligned during manufacture of the film by stretching or by applying electric or magnetic fields.

With the crystals aligned, the sheet tends to absorb light which is polarised parallel to the direction of the crystal alignment, but transmits light which is polarised perpendicularly to it. This material, known as J-sheet, was later replaced by the improved H-sheet Polaroid. H-sheet is a polyvinyl alcohol (PVA) polymer impregnated with iodine.

During manufacture, the PVA polymer chains are stretched such that they form an array of aligned, linear molecules in the material. Because of the way that a polarised light wave interacts with these molecules, the sheet of Polaroid only transmits the components of the light with the electric field vector perpendicular to the molecular alignment. The direction which passes the polarised light waves is called the transmission axis. The Polaroid sheet blocks the electric field vector component that is parallel to the molecular alignment.

Activities that benefit from polarised lenses include driving, sailing, skiing, fishing and flying.

Drivewear

A development in both photochromic and polarising technology came in the form of the Drivewear lens (Figure 11). Developed by Younger Optics and Transitions, this laminated lens offered the first lightly tinted polarising filter combined with a visible light photochromic and traditional UV photochromic functions.

[CaptionComponent="2665"]

In overcast conditions only the pale yellow/green polarising filter (approximately 35 per cent LTF – Class 2 tint) is evident, providing glare reduction and contrast enhancement while driving. In brighter conditions, even though most windscreens filter out UV, the photochromic element will be activated by visible light and will darken to a copper/brown colour (enhancing reds and greens) with the LTF decreasing to approximately 22 per cent (Class 2).

[CaptionComponent="2666"]

Outside the vehicle the UV rays are no longer blocked by the car windshield and the layer of Transitions photochromic molecules become active. This UV photochromic element darkens the lens yet further to approximately 15 per cent LTF (Class 3 tint) and the lens colour changes to dark brown.

Mirror coatings

One final aspect of sun protection worthy of note is that of mirror coatings. Although the importance of UV absorption cannot be overstated, the luminous intensity of direct and indirect reflected sunlight should also be considered. Bright sunlight provides a luminance of approximately 100,000cd m2 at the Earth’s surface.

If viewed directly, the intensity of this energy will cause rapid and permanent photochemical damage to the eye. Even if viewed indirectly, nearly 80 per cent is still reflected by snow and 10 per cent by water. Activities that can benefit from mirror-coated lenses include skiing, sailing, climbing and flying.

Applied as a coated layer of reflective molecules on the front surface of a lens, a mirror coating will increase the surface reflectance and so avoid the need for a very low transmission tint that might otherwise adversely affect the wearer’s visual acuity.

A dark tint and/or polarising filter are normally specified at the same time. In recent years it has become fashionable to wear half-silvered or flash mirror coated lenses in either full or graduated form with a pale tint, especially on commercially available sunglass ranges, and many manufacturers also offer such coatings on their prescription ranges.

Vocational tints

Pale tints can be useful for indoor use, especially in office environments and other work places where natural daylight is poor, and fluorescent lighting is prevalent. Specialist tints like Norville’s ‘Dot Com’ range and Vista Mesh have been developed in conjunction with reflection-free coatings to filter out wavelengths which include much of the flicker created by fluorescent lamps. Tinted lenses are also widely used in some vocations utilising specific spectral filters to protect the eye.

Examples of such applications include dentistry where orange UV550 and UV600 lenses are worn to shield the eyes from powerful UV lamps used to cure white fillings. Welders require even higher levels of UV absorption combined with very low transmittance tints, and glass blowers benefit from glass didymium lenses that block the yellowish light emitted by the hot sodium in glass.

Glass lenses that contain lead are used to absorb X-rays. Research indicates that cataracts may develop due to exposure of handling radioactive materials. Eyelid dermatitis and conjunctivitis may possibly be caused by X-rays. The lens is clear (not tinted) and has a refractive index of 1.80, density 5.18g/cm3 and Abbe number of 25.4. An amethyst contrast enhancing lens utilises rare earth compounds in its composition to achieve unique colour enhancing characteristics.

This concept works by selectively positioning transmission across the spectral regions. This helps to improve colour discrimination between different colour objects. Its use includes hot glass workers, high ambient light conditions, glowing heat sources eg kilns, acetylene torch work in jewellery, enamelling as well as leisure and occupational activities including golf and in particular VDU use. Although it has a low luminous transmittance of 38 per cent, it is not recommended for sun protection as it has poor UV absorption.

Therapeutic filters

In recent years a number of organisations have begun to develop and use specialist coloured filters to alleviate the symptoms of some conditions. Probably the most cited of these is the use of tinted lenses to help visual stress. Colorimetry as it has become known, employs a series of tests and highly accurate, prescribed tints to alleviate various visual/perceptual disorders associated with dyslexia, autism and other developmental disorders.

Psychological research has shown that certain coloured lenses have even been found to affect a wearer’s mood or help with phobias like motion sickness and vertigo. Therapeutic lenses have also been prescribed for some years now to reduce the onset of photosensitive migraine, and although many therapeutic lenses are now available, there is still strong debate over their effectiveness. Practitioners should be wary about prescribing such lenses without first seeking advice from experienced practitioners and organisations that specialise in those specific disorders.

Summary

When prescribed with care and reason, tinted lenses can considerably enhance both the wearer’s vision and the functionality of their spectacles, bringing happy patients back to the practice and providing added value to each dispense. The next article in the series will discuss reflection-free coatings.

Further reading

Fowler C and Latham Petre K (2001). Spectacle Lenses: Theory and Practice Butterworth Heinemann Oxford UK.

Jalie M (1984). Principles of Ophthalmic Lenses 4th edition, The Association of British Dispensing Opticians London UK.

Jalie M (2008). Ophthalmic Lenses & Dispensing 3rd Edition. Butterworth Heinemann Oxford UK.

Norville Optical (2012). Prescription Companion.

Ophthalmic Lens Availability (2014). The Association of British Dispensing Opticians London UK.

Tunnacliffe A H (2003). Essentials of Dispensing. 2nd Edition ABDO.

? Andrew Keirl is an optometrist and DO in private practice, associate lecturer in optometry at Plymouth University, ABDO principal examiner for professional conduct in ophthalmic dispensing, ABDO practical examiner and external examiner for ABDO College