This article looks at the sixth and seventh generation of progressive lens designs.

Sixth generation progressive designs

In 2006, Essilor’s continuing research to perfect the Varilux lens led to a new design which retained all the best features of previous generations and applied the very latest technology to both the design and method of manufacture of the lens. This enabled the design to address the comfort of the field of vision and to provide a significant improvement in the overall effect of the lens in wear.

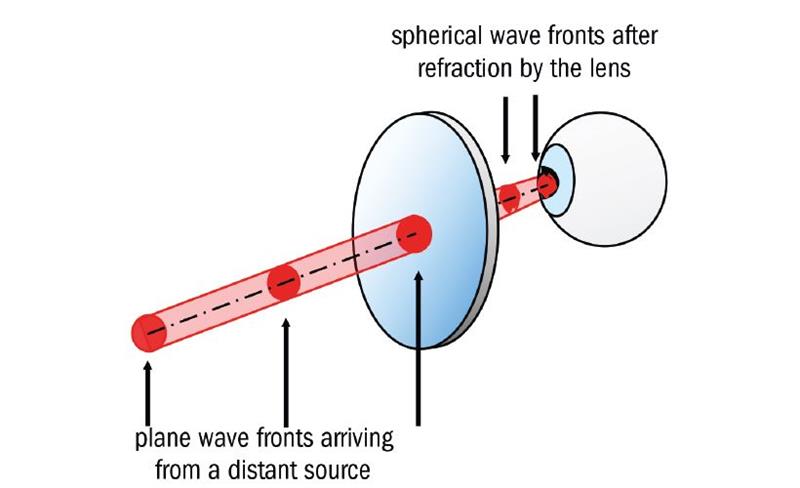

Ophthalmic lens design is normally concerned only with foveal vision, where the visual acuity is at its maximum and the resolution is, therefore, highest. The criterion for a best form spectacle lens is that it should produce a good quality image on the fovea. Since the pupil diameter is small, it is usual to consider the effect of the lens only upon single rays of light which meet the lens at a point. At night time, however, the pupil may increase its diameter several times and the new analysis method employed for the Varilux Physio design assumed a finite pupil diameter of 6mm. At this diameter, the light emanating from the lens is not just a single ray but, instead, a narrow pencil of light within which, for an ideal spherical lens, the emergent wave front should be spherical (figure 1). For distance vision, the wave front aberration in the refracted pencil is defined as any departure from a spherical surface concentric with the second principal focus of the lens. Owing to the peculiar nature of a progressive surface, the refracted pencil can only be spherical over a small area of the lens, but any deformation can be modified by adjustment of the concave surface of the lens. This is the principle of Essilor’s Wavefront Management System, employed in their sixth generation design, which set out to provide the optimum acuity for distance vision.

Figure 1: Ideal wavefront management

In the case of a spherical distance correction, the shape of the wavefront is calculated after emergence from the lens and any departure of the wavefronts from a sphere, is corrected by suitable adjustment of the form of the concave surface. The change in shape from the form of a sphere in a supposedly spherical wavefront can be described mathematically in several ways. It can be shown that a polynomial could be derived, using the methods described by Seidel in the 19th century, based upon the power series obtained by Taylor’s theorem for the sine of an angle. The method suggested by the ANSI Z80.28:2004 publication, Methods for reporting optical aberrations of the eyes1 is by means of Zernike polynomials2 which break down the departure from a sphere into ascending orders of the pupil radius.

Wave front changes are often depicted by colour diagrams which show where, and how, the wavefront has departed from its spherical form. If there were no changes to the spherical form of the wavefront as the beam passes through the centre of the eye’s entrance pupil, the representation would be all green in colour as shown in figure 2a. Different forms of aberration are depicted in the figures, where warm red colours mean the wavefront is in advance of itself and cooler blue colours, behind. For example, the second row (figure 2b, Z1 and Z2) depicts the wavefront after passing through a prism where the beam is tilted such that, in the left-hand representation, Z1, the wavefront has tilted in the y-plane about the x-axis, the upper portion of the beam is in advance of the position of the centre of the beam and the lower portions are behind the position of the centre of the beam.

Figure 2: Representation of wave front aberration in terms of Zernike polynomials

In the ophthalmic field, the 1st and 2nd orders are the well-known terms: tilt (prismatic effect), (Z1 and Z2), defocus (power error, MRE, Z4), and astigmatism, Z3 and Z5. These so called ‘lower-order aberrations’ are linked directly to the prescription (figure 2c). The astigmatism is illustrated using the components, C0 and C45, used in astigmatic decomposition3. The remaining aberrations are referred to as ‘higher-order aberrations’. It should be noted that this term relates to Zernike coefficients and not to the descriptions suggested by Seidel, third-order, fifth-order etc, as described in earlier literature on lens design.

In the case of an astigmatic distance correction, the form of the pencil should be toroidal with the centre of each of the two principal circular wavefronts coinciding with the point where the line focus intersects the optical axis. It will be understood that only the shape of the wavefront as it leaves the lens is being considered. Its form after refraction by the cornea, of course, is unknown. However, if the prescription in the distance portion of the lens is designed to fully correct the subject’s ametropia in every direction of gaze, the wavefront leaving the posterior surface of the crystalline lens should be spherical and concentric with the fovea. Needless to say, this utopian state of affairs cannot be obtained with a progressive surface whose different zones possess both the consequences of Minkwitz surface astigmatism and the results of the blending processes chosen by the designer. One of the significant effects of the asymmetrical nature of a progressive surface can be considered as the effect of coma, added to astigmatism, which gives rise to the higher-order aberrations depicted in figure 2. Essilor described their attempts to minimise these effects as Coma Control in the distance area of the Varilux Physio lens.

The intermediate zone of a progressive lens, within which the power increases from distance to near, inevitably suffers from astigmatism, which increases as the eye roams further in a horizontal direction from the meridian line running down the centre of the progressive surface. It is well known that in the presence of uncorrected astigmatism, the eye will find it easier to discern the proper shape of an object if the axis of the astigmatism is orientated vertically or horizontally. Acuity is generally poorest when the axis is oblique. This is particularly true when the subject is viewing text which tends to be recognised, mainly, from the vertical strokes of the individual letters.

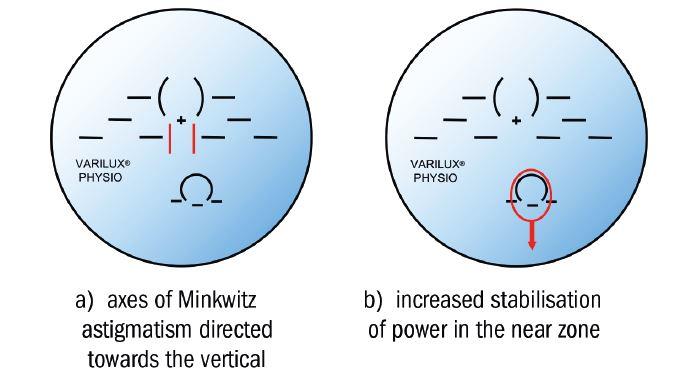

The importance of the axis direction of the residual aberrational astigmatism was recognised by the designers of Varilux Physio who used their Wavefront Management System both to reduce the amount of unwanted astigmatism, and to direct its axis towards the vertical meridian (figure 3a). That lateral vision in the intermediate zone is improved, was clearly indicated by wearer tests, where subjects obtained a wider field of perception in this region of the lens. This is just one of the gains which were reported in the wearer tests to which the new design was subjected in direct comparison with Essilor’s previously most popular design, the Varilux Comfort lens.

Figure 3: Two further characteristics of the Varilux Physio design; enhanced PZ and NP zones

The importance of providing a deep and wide near zone in which the wearer can obtain the benefit of the full near addition, was also a major consideration in the design of Physio. By means of the newly introduced Wavefront Management System the designers were able to stabilise the optical characteristics of the design over a larger region of the near zone (figure 3b).

Accuracy in the production of the new lens design was ensured by employing computer numerically controlled (free form) grinding and polishing technology. For the new method of production of Physio, Essilor introduced Twin Rx Technology where the refraction is analysed at each point on the back surface through which the chief ray of the pencil passes, and the convex progressive surface adjusted to ensure that optimum performance is obtained for all directions of gaze. Sophisticated computing software was developed to carry out this Point by Point Twinning of the convex and concave surfaces, in order to determine the complementary surface which had to be manufactured to ensure the required optical performance is obtained. Thus, instead of only one power for each base curve having the ideal optical performance, this method of advanced digital surfacing enabled each lens to be manufactured individually to provide the optimum performance.

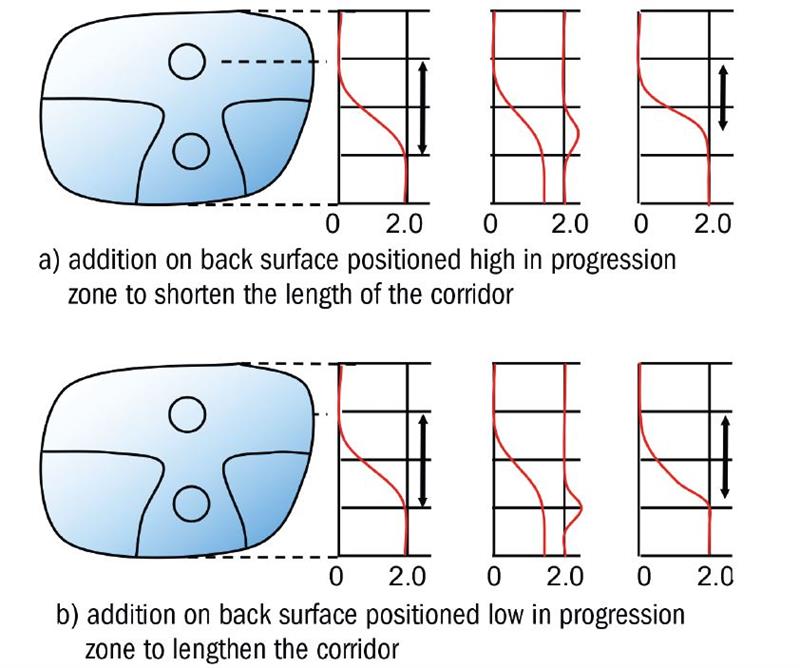

One of the first applications of dual surface progressive design from the Essilor group was the introduction of a variable corridor length in the Anateo PdM design from their BBGR division. As shown in figure 4, the back surface incorporated a small part of the full near addition which could be positioned higher or lower on the back surface in order to shorten, or lengthen, the corridor as required by the practitioner.

Figure 4: BBGR Anateo PdM double surface progressive design

A further development was the introduction of a near vision chart, called an EyeTab, which, by means of transponders, measures the distance at which the subject holds their reading material to ensure that the actual working distance is incorporated in the calculation for the inset for their lenses. This design was known as the Anateo MIO.

The manufacture of the original Hoyalux iD lens did not begin until the prescription was received by the laboratory. Each lens was custom designed and each surface individually worked by means of free form surfacing in order to integrate them to provide all the correct parameters for the prescription. Although this production method resulted in an optimum lens, it required a lengthier processing time than that which can be obtained by the use of semi-finished blanks, where one surface has already been fully completed.

Since the principle of the Hoyalux iD lens, is to allow each surface to contribute to the final addition, the designers at Hoya considered methods by which the integrated double surface progressive lens could be provided in semi-finished form. The result was the Hoyalux iD LifeStyle lens. With this new design, no matter what the final addition has to be, the front surface of the lens incorporated an addition of about +3.00 DC x 180 to provide the vertical progression component whereas the back surface incorporates an addition which when combined with the convex surface results in the required spherical addition. Thus, if the addition required is +2.00 D, then the concave surface would contribute an addition of -1.00 DC along 90 and +2.00 DC along 180. Figure 5 shows a typical configuration for the specification, plano add +2.00 D.

Figure 5: Hoyalux iD LifeStyle double surface design with fixed vertical addition on the front surface

Several manufacturers introduced progressive lenses whose surfaces were designed to prioritise the performance of a specific area of the lens. A 2004 Patent assigned to Rodenstock4 described eight different possible applications, each of which would benefit from different design characteristics for the distance, intermediate and near zones of the lens. The surface configurations identified in the patent include:

- standard Ω balanced for distance, intermediate and near

- computer monitor Ω intermediate area prioritised

- work at the desk Ω near area prioritised

- driving Ω asymmetric design with distance zone prioritised

- pilot design Ω near vision zones provided in both the top and bottom regions of the lens

- sports Ω particularly ball games involving a bat requiring clear vision from infinity down to one metre

- watchmaker Ω clear vision at very short distances

- surgeon – substantially average distances

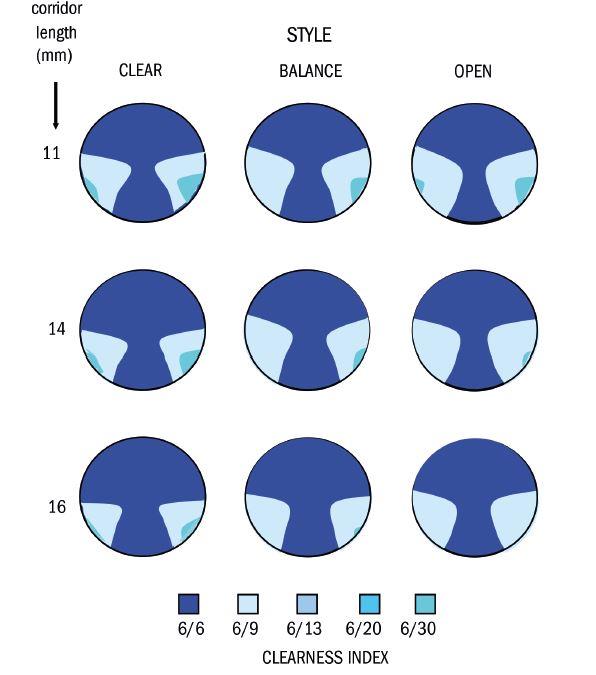

Similar characteristics were proposed by Hoya. The Hoyalux iD Mystyle lens introduced a choice in the basic surface design, depending upon the wearing characteristics of the subject, including the characteristics of any previous design which the subject might have worn. By means of the MyStyle iDentifier, the design profile and most effective corridor length, 11mm, 14mm or 16mm is selected for the subject depending upon the answers to a series of questions prompted by the iDentifier. The three basic designs range from the hardest design known as MyStyle Clear, which offers an extra wide deformation-free distance part with a clear and free field of vision; a balanced design known as MyStyle Balance, whose structure offers a more dynamic lifestyle, in which focused vision and stability at all angles and in all situations is required, through to the softest design, known as MyStyle Open, whose soft design does not place high demands on specific vision areas but instead the focus is on optical balance, a soft progression structure and a wide reading area. Each design is made with three different corridor lengths, 11mm, 14mm and 16mm. The illustrations shown in figure 6 show the mapping of Hoya’s Clearness Index from the areas (dark blue) in which 6/6 vision can be expected, to green, in which 6/30, or worse, vision is to be expected. In the light blue areas the vision worsens progressively from about 6/9 to 6/30.

Figure 6: Hoyalux iD MyStyle designs

Nikon introduced a double surface progressive design known as the SeeMax Progressive which shared the near addition between the two surfaces, the concave surface being of atoroidal progressive form which Nikon described as an aberration filter.

Seiko also introduced a new design known as the Synergy X in the UK and Proceed III in the USA, using their 1.67 index monomer and multipurpose coating process.

Using technology from Crossbows Optical in Northern Ireland, and their Kodak branding, Signet Armorlite introduced a new design called the Kodak Unique, which employed a spherical front surface and a concave, atoroidal, progressive surface.5 A new feature of the design was the method by which the corridor length was automatically selected by the software which examined the fitting height and vertical box dimension of the finished lens shape. This feature ensured the corridor length which was chosen by the software allowed a sufficiently deep near portion of the lens for the subject to obtain an adequate near vision field.

The sixth generation, free form progressive designs from Rodenstock employ a convex spherical surface and a free form aspherical or atoroidal progressive surface which can be fully personalised for wearer characteristics mentioned earlier, as well as the frame mounting characteristics such as vertex distance, pantoscopic and face form angles, inset, etc. Special surface modifications were also made for high power plus and minus lenses, known as Impression Hyperop and Impression Myop, both of which are also available in XS (short corridor) versions.

Shamir’s Autograph II design is a personalised progressive design incorporating the wearer’s individual fitting characteristics. It employs a spherical front surface and free form concave surface with corridor lengths of 11mm, 13mm, 15mm or 18mm enabling the design to be fitted into both shallow and deep spectacle frames.

The sixth generation progressive design from Sola is known as the HDV. In addition to full optical optimisation for the wearer’s prescription, which is utilised for all of Sola’s ‘High Definition’ free form progressive lenses, the lens offers a variable corridor length that is customised, using morphing technology, to the wearer’s frame size and fitting height down to 13mm. Sola’s design software creates a progressive lens design in real time using the wearer’s prescription and frame measurements, immediately prior to fabrication. The lens design is then fully realised on the back surface, along with the prescription curves, using free form surfacing.

With the intention of correcting higher-order aberrations along the principal sight direction, Zeiss introduced an auto-refractor with a built-in aberrometer, the i-Profiler, designed to measure both the prescription and the higher-order aberrations of each eye. An optimisation algorithm, called i-Scription, then fine-tunes the prescription to incorporate both the prescription and a correction for the higher-order aberrations of the eye along the principal sight direction. Unlike the wavefront analysis of the two lens surfaces employed in the design of the Varilux Physio, the resulting lens also incorporates a correction for the wavefront aberration of the eye itself, when it is viewing through the primary visual point on the lens. It goes without saying that as the eye rotates behind the lens, the visual axis is directed through other points on the lens, and the wavefront aberration correction at the centre of the field is no longer valid for the shape of the wavefront in the refracted pencil and possibly, that introduced by the eye’s refracting surfaces will change with the viewing direction. For optimum correction, wearer fitting characteristics can also be incorporated into the new Zeiss Individual EyeFit design.

Seventh generation progressive designs

Essilor’s seventh generation progressive design, the S-series, is a double-surface progressive design. Introduced in 2012, it incorporated three new features, Synchroneyes, to ensure a wide field of balanced vision, Nanoptix, to provide the best form for distance and near and to ensure accuracy of the surface was maintained during manufacture. In the case of the Varilux S Ω 4D design, it was also ensured that the performance of the lens in front of the dominant eye was optimised it terms of the positioning of the meridian line of the progressive surface.

Zeiss had introduced the principle of Horizontal Symmetry in 1983, which was beneficial in cases where the same semi-finished blank could be used for each eye. Then, provided that the prescriptions were the same, or very nearly so, in the right and left eyes, when the eyes undertake version movements, the symmetry principle is maintained and vertical differential prismatic effect would not hinder comfortable binocular vision (figure 7a). However, when the prescription is different for each eye, as shown in figure 7b, the property of horizontal symmetry is lost between corresponding points and the eyes need to make a greater effort to achieve fusion and comfortable binocular vision. If the difference in prescription is large, binocular vision might not be achieved at all. Synchronised vision for a pair of lenses at all points on the lenses, despite differences in prescription, was achieved by the Synchroneyes process. To apply Synchroneyes, lenses must be ordered as a pair since the software must take into account the performance of each lens during the calculation routine.

Figure 7: Corresponding visual points in version movements of eyes – Synchroneyes

The significance of Nanoptix can be understood by considering the information provided by the Tscherning Ellipses on the best forms of spectacle lenses for distance and near vision.3 When the Ostwalt bending for point focal lenses is considered, the lens forms required for near vision, are about 2.00 D shallower than their distance vision counterparts over most of the range.

Consider a +4.00 D lens which is to be used for distance vision. To obtain a point focal form for a normal index material, a +10.00 D front curve would be required. However, if it is known that the lens is to be used only for near vision, the best form would require a front curve of only +8.00 D. This reduction in the bending of the lens for near vision is exactly what is achieved by the Nanoptix process. To make the distance specification for the prescription, +4.00, Add +2.00, the front curve might be +10.00 D in the distance area, reducing to +8.00 D in the near area (figure 8). This creates an addition of minus two on the front surface. In order to obtain a near addition of +2.00, the back surface must incorporate an addition of +4.00 D. This is achieved by working the back surface with a nominal -6.00 D curve in the distance area and a -2.00 D curve in the near area. Very careful positioning of each surface is essential to produce the lenses accurately and sophisticated methods for the blocking and digital surfacing of each side had to be developed to ensure the finished lens corresponded precisely with the design specifications.

Figure 8: Varilux S-series double surface progressive design – Nanoptix

The third feature introduced with the Varilux S-series followed on from research undertaken in Essilor’s physiological optics laboratories concerning the role of the dominant eye in binocular vision. The research discovered a unique characteristic of the dominant eye. The experiment involved blurring, first the dominant eye, then the non-dominant eye, to see if the visual reaction time varied. When the non-dominant eye is blurred the difference is small. When the dominant eye is blurred the visual reaction time increases significantly. Hence it is clear the dominant eye is the directional guide for the fellow eye and triggers its vergence movement, reaching the object of interest faster. By taking into account the leading role of the dominant eye, ‘4-D’ technology could improve the reaction time of the wearer. The design of the lens in front of the dominant eye is, therefore, prioritised to provide the most comfortable binocular vision.

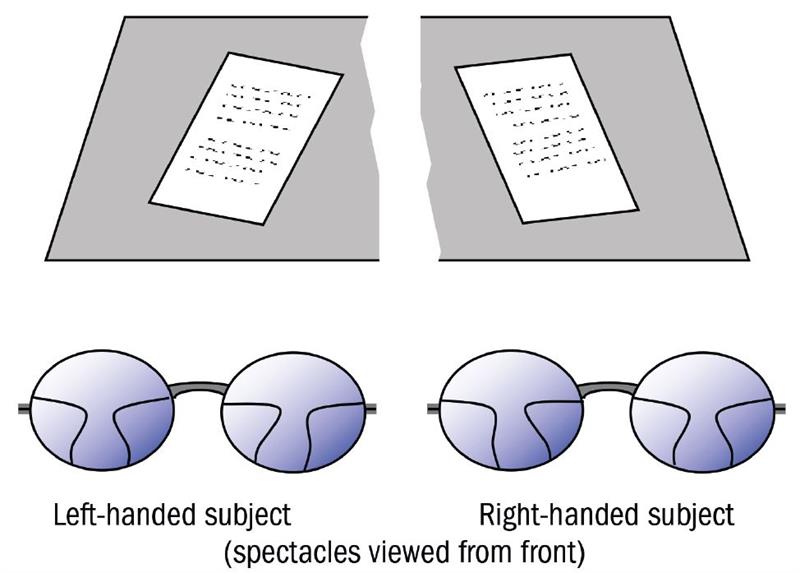

Figure 9: Intuitiv design incorporating adjustment for handedness (BBGR)

The latest design from BBGR takes into account whether the subject is right or left-handed and positions the meridian line of the lens accordingly (figure 9). Their research into the ergonomic posture of right and left-handed subjects and the positioning of the material on the table top before them, has resulted in the claim that an increase in the near vision field will result from a suitable adjustment of the position of the centre of the corridors of clear vision (BBGR Intutiv lens).

Professor Mo Jalie is a visiting professor at Ulster University and author of the new edition of Principles of Ophthalmic Lenses.

References

1 American National Standards Institution, ANSI Z80.28:2004, Methods for Reporting Optical Aberrations of the Eyes

2 Zernike F, (1934) Beugungstheorie des Schneidenver-fahrens und seiner verbesserten Form, der Phasen- kontrastmethode. Physica. 94, 689

3 Jalie M, (2016) Principles of Ophthalmic lenses, 5th Edition, ABDO, Godmersham.

4 Baumbach P et al, (2004), US Patent 6685316 Method of Manufacturing Progressive Ophthalmic Lenses.

5 Steele T, McLoughlin H, Payne D, (2006), US Patent 7033023 Progressive Addition Power Lens. Assigned to Signet Armorlite Inc. UK application 2002.