Life is different today. It is faster. Many of us have internalised an ethic that pushes us to work and play as hard as possible.

In this driven environment, we charge from activity to activity. Our eyes jump from computer screens to smartphones to the person talking to us as we text; or we watch our child’s football game while jotting notes for work and simultaneously emailing on a tablet. Working as hard as we do, it is no wonder that we are often worn out at the end of such a demanding day.

Our eyes experience demanding days, too. The myriad activities we pursue – and the changing environments we experience as we go from home to car to work to sports to the movies and back home again – all affect our eyes. And millions of us do all this while wearing contact lenses.

While we are going about our demanding days, our eyes and eyelids are hard at work, maintaining clear vision and a healthy ocular surface by blinking at least 11,000 times per day. Blinking requires energy, and while the energy required for a single blink is insignificant, the energy required for 11,000 blinks every day may be considerable.

Just how much effort we put into blinking can be calculated using an equation where ‘work’ is the product of force × distance.

In this case, the distance is the 10 or so millimetres the lid travels during the blink cycle, and the force is the effort required to overcome resistance to the blink, which comes largely from friction between lid and the cornea (or a contact lens, if one is being worn). The energy expended to overcome friction is called frictional energy.

The frictional energy between surfaces is a function of two things: (1) whatever lubricant exists between the surfaces and (2) the state of the surfaces themselves.

For example, it is much easier – and, therefore, demands less energy – to push a large box over a shiny polished floor than over a rough concrete pavement. Although there are factors in addition to roughness that determine frictional energy, it is clear that surfaces with differing degrees of roughness will require different levels of force to obtain the same degree of motion.

Frictional energy and the eye

Our eyes do ‘work’ during the blink process because energy is required to overcome the frictional forces resisting eyelid movement. Fortunately, the tear film lubricates the lid and ocular surface. But what happens if friction between the lids and ocular surface increases as the day wears on? This could be the case, for example, with a contact lens whose surface becomes less lubricious and less smooth as drying and deposits take their toll throughout the course of a day.

In this situation, the repeated movement of the eyelid over an increasingly resistive surface thousands of times throughout the day can create a significant amount of additional ‘work’ for the eye. This correlates with the common observation that many patients who are comfortable in their contact lenses in the morning start to experience ocular symptoms of fatigue as the day progresses.1

What science tells us

Tribology is the science of the interaction between surfaces in motion. It deals in a rigorous way with things we experience every day: friction, lubrication and wear.

In recent years, tribology has been applied to the study of factors that influence comfort in contact lens wear.2 It makes intuitive sense that, all other things being equal, the less friction between the eyelid and a contact lens, the more comfortable and the less symptomatic contact lens wear will be. And, indeed, there is evidence to support this.3

Because more people drop out of lens wear as a result of discomfort than for any other reason, it is little wonder that factors related to discomfort – like friction and lubrication – are of great interest to the contact lens industry and practitioners.1,4

The physics of comfort

Friction is the force that acts at the interface of two solid surfaces to resist their sliding past one another.5 The level of resistance is a property of the surfaces called coefficient of friction (CoF). CoF is derived from two separate forces: (1) the force needed to keep the objects sliding and (2) the force holding the surfaces together (the ‘normal’ force). Both forces may be directly measured and a CoF calculated as shown in the following equation:

CoF = (Frictional Force) / (Normal Force) = (Ft) / (Fn)

The larger the CoF, the greater the resistance as a result of friction and, thus, the greater the frictional energy required to slide the surfaces past one another over a given distance. When both the frictional force and the distance through which it works are known, the frictional energy can be determined using the equation below:

Frictional Energy (Ef) = Sliding Work = Frictional Force (Ft) × Distance (D)

Measuring frictional energy

We have said that the work done by the eyelid in blinking is equal to the frictional energy required to move the lid over the cornea (or a contact lens). Additionally, the frictional energy that is generated is a function of the CoF, as both equations contain the frictional force term. Because a relationship between CoF and contact lens comfort has been established, the measurement of frictional energy loss in a simulated blink should also give us insight into how different contact lenses will perform on the eye.

Although it can not be measured directly, a number of devices for estimating the frictional forces between the eyelid and a contact lens have been described, including instruments that aim to replicate the critical features of the on-eye situation.1 These in-vitro and ex-vivo measurements made under physiologically relevant conditions represent a significant step forward in predicting contact lens comfort.

Of course, for comparisons of lubricity to be meaningful, they must replicate not just the conditions of the eye but the physiology of contact lens wear. For example, it is one thing to compare the frictional energy loss with two fresh-from-the-package contact lenses; but can this tell us what the lenses will be like after they have been worn for 10, 12 or 14 hours?

To be truly applicable to contact lens wear, it is necessary to look at friction through time and under the conditions that the lens is likely to be worn.

Frictional energy throughout the day

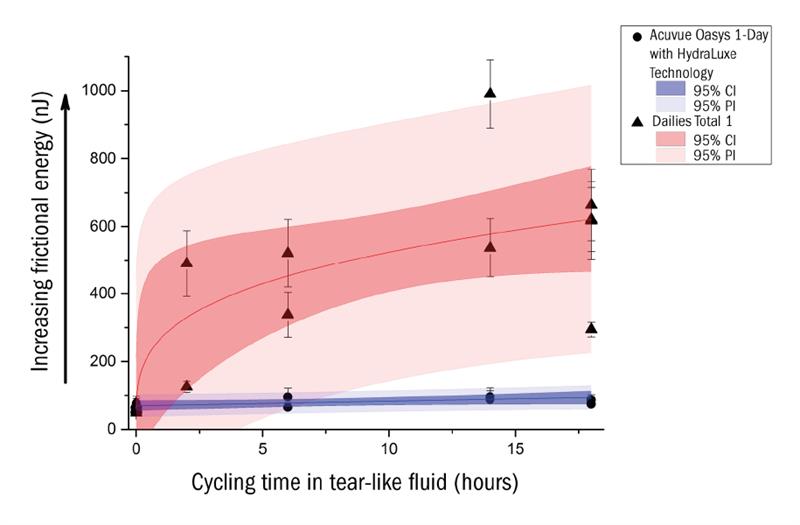

In a simulated eye-blink experiment using a microtribometer (figure 1), a device that directly measures the normal force and frictional force, enabling the determination of frictional energy, Acuvue Oasys Contact Lenses 1-Day with HydraLuxe Technology were cycled in a tear-like fluid for up to 18 hours. The results were impressive. In figure 2 the blue line represents the frictional energy of the lenses measured through time that approximates a long day of wear, in this case, 18+ hours. It is important to note that the frictional energy starts low and stays low for the duration of lens wear. If the line instead curved upwards, that increase in frictional energy could contribute to a degradation in performance.

Figure 2: Frictional energy of Acuvue Oasys 1-Day with HydraLuxe Technology, measured by a tribometer. Note the low and high reproducible values recorded. Dailies Total1 has 2X the frictional energy of Acuvue Oasys 1-Day with HydraLuxe Technology (95% confidence and prediction intervals are shown)

Lens-to-lens variability, as indicated by the lighter blue ‘spread’ in the confidence intervals, is also very tight, meaning that the frictional energy of the lenses are consistent from one lens to the next. Together, these factors suggest a favourable and robust tribological profile for the lenses under physiological conditions.

When the same simulated eye blink experiment was repeated using Dailies Total1 (Alcon) we found that it had two times the frictional energy of Acuvue Oasys 1-Day Lenses with HydraLuxe Technology (estimated at the 14 hour time point comparing mean data for Acuvue Oasys 1-Day Lenses and lowest predictive intervals for Dailies Total1 (figure 2). This may be because the water gradient design in Dailies Total1 (with nearly 100% water at the surface and 33% at the core) has a non-uniform composition throughout the lens, and a high surface roughness as measured by atomic force microscopy (AFM).

Creating less work

What is it about Acuvue Oasys 1-Day Lenses with HydraLuxe Technology that gives them such robust performance in tribological testing? Several aspects of the lens may be responsible. First, HydraLuxe Technology works continuously throughout the day to lubricate and moisturise the lens. On the eye, the lens supports the tear film because the lens is like the tear film.

In addition, the lens is extremely smooth. This has been demonstrated via transmission electron microscopy (TEM), which enables examination of contact lens surfaces under high magnification (ie sub-micron dimensions), allowing precise visualization of the surface and bulk or matrix of a material. This has also been corroborated by atomic force microscopy (AFM) measurements.

Additionally, these lenses also have a unique tear-infused design with an enhanced network of tear-like molecules and highly breathable silicone that integrates with the patient’s own tear film. This uniform tear-like network exists throughout the entire lens; it is not just a surface coating. The data shows that the low frictional energy profile of the lens lasts throughout the day

Proper moisture and lubrication

Innovation leads to advancements and, ultimately, to patient benefits. Acuvue Oasys 1-Day with HydraLuxe Technology lenses have demonstrated consistently low frictional energies through time when measured using a physiologically relevant methodology. Perhaps this is because the tear-infused design integrates key tear-like components – not just water – to moisturise and lubricate the lens throughout the day.

In addition, the lenses are exceptionally smooth – as demonstrated by TEM and corroborated by AFM – and rather than employing a thin surface coating, they maintain a uniform, tear-like network throughout the entire lens. Clinical studies and feedback from eye care professionals and patients will determine whether these lenses deliver the on-eye performance that their impressively low and stable frictional energy predicts.

Charles Scales, PhD, is principal scientist for Johnson & Johnson Vision Care, Inc, USA.

Brian Pall, OD, MS, FAAO, is senior principal research optometrist, Johnson & Johnson Vision Care, Inc, USA.

This article is based on an original article from the 2015 Special Edition of Optometric Management, optometricmanagement.com, published monthly by PentaVision LLC.

References

1 Nichols JJ, Willcox MDP, Bron AJ, et al. The TFOS International Workshop on Contact Lens Discomfort: Executive Summary. Invest Ophthalmol Vis Sci. 2013;54:TFOS7-TFOS13.

2 Roba M, Duncan EG, Hill GA, Spencer ND, Tosatti SPG. Friction measurements on contact lenses in their operating environment. Tribol Lett. 2011;44: 387-97.

3 Coles-Brennan C, Brennan N. Coefficient of Friction and Soft Contact Lens Comfort. Presented at American Academy of Optometry Annual Meeting. Phoenix AZ, October 24, 2012. Poster 70.

4 Dumbleton K, Woods CA, Jones LW, Fonn D. The impact of contemporary contact lenses on contact lens discontinuation. Eye Contact Lens. 2013 Jan;39(1):93-9.

5 Subbaraman LN, Jones LW. Measuring Friction and Lubricity of Soft Contact Lenses: A Review. Contact Lens Spectrum. June 2013. Accessed August 28, 2015 atclspectrum.com/articleviewer.aspx?articleID=108560